Introduction – Precision Moulding for Modern Industries

From consumer goods to automotive and electronics, molding technology is the backbone of large-scale production. A professional Moulding maker ensures that molds are designed and manufactured with precision, enabling businesses to achieve efficiency and cost-effectiveness.

Alongside this, advanced Plastic molding and Plastic injection molding solutions are revolutionizing how industries produce high-quality, consistent, and durable plastic components.

Moulding Maker – Crafting the Foundation

A Moulding maker plays a critical role in manufacturing. They design and build the molds that form the foundation of mass production.

Key Responsibilities of a Moulding Maker:

- Designing molds for complex geometries

- Ensuring durability for long production cycles

- Conducting mold-flow analysis for better performance

- Creating cost-efficient solutions for high-volume production

Without skilled moulding makers, consistent industrial-scale manufacturing wouldn’t be possible.

Plastic Molding – Shaping the Future

Plastic molding is the process of shaping plastic into desired forms using specialized molds. It’s used across industries for:

- Packaging materials

- Automotive components

- Consumer electronics

- Medical devices

Benefits include:

- High repeatability

- Cost-effectiveness for bulk production

- Flexibility in product design

- Consistent quality output

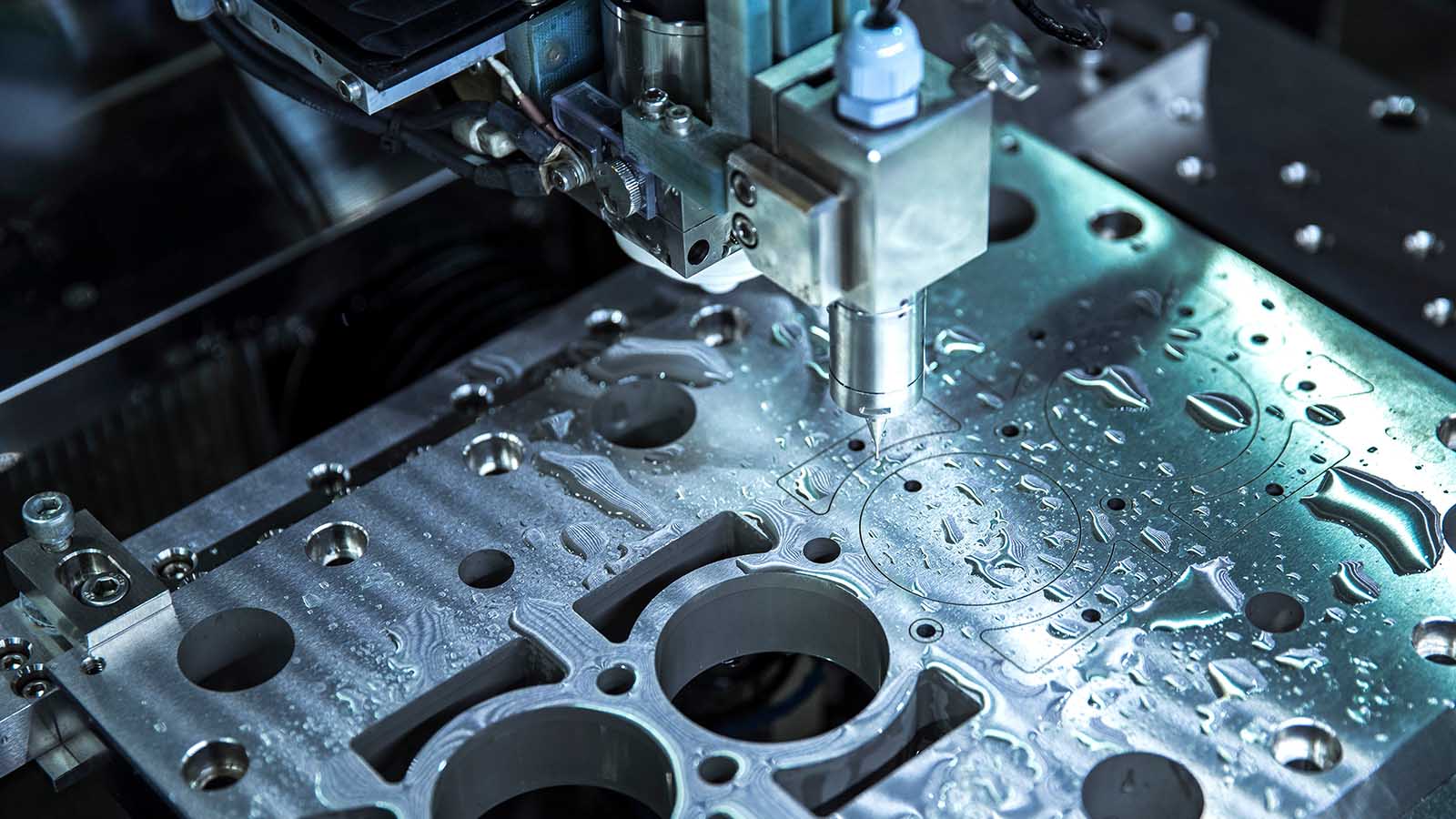

Plastic Injection Molding – Precision at Scale

Plastic injection molding is one of the most popular methods of plastic manufacturing. It involves injecting molten plastic into a mold cavity under pressure.

Advantages of Plastic Injection Molding:

- Produces complex parts with tight tolerances

- High efficiency for mass production

- Reduced material waste with optimized cycle times

- Ability to use multiple types of plastic materials

This method is ideal for producing durable, scalable, and high-precision products.

Why Choose Engineeringi?

Engineeringi provides end-to-end molding solutions:

- Expert Moulding makers with advanced design capabilities

- Industry-standard Plastic molding for various sectors

- Reliable Plastic injection molding with consistent quality

- Custom solutions tailored to client requirements

By combining innovation and precision, Engineeringi ensures world-class manufacturing support for global industries.

Conclusion – Engineeringi Advantage

From skilled Moulding maker services to efficient Plastic molding and advanced Plastic injection molding, Engineeringi empowers businesses with scalable and cost-effective manufacturing solutions.

For industries seeking precision, durability, and efficiency, Engineeringi is the trusted partner in molding excellence.

FAQs – Moulding & Plastic Injection Solutions

Q1. What is the role of a moulding maker?

They design and manufacture molds used for mass production of plastic products.

Q2. What industries rely on plastic molding?

Automotive, packaging, electronics, and consumer goods industries.

Q3. Why is plastic injection molding so popular?

Because it allows cost-effective, high-volume production of durable and complex parts.

Q4. How does Engineeringi ensure mold quality?

By using advanced mold-flow analysis and durable materials for long production cycles.Q5. Can Engineeringi handle custom projects?

Yes, Engineeringi specializes in customized molding solutions based on client needs.

Leave a Reply