Introduction to Electromagnetic Shielding Materials

In an increasingly interconnected world, the appliances and devices we use are constantly bombarded by various forms of electromagnetic interference (EMI). This interference can lead to significant disruptions in performance, compromised communications, and, in some cases, costly damage to sensitive electronics. To combat these issues, industries and consumers alike rely on electromagnetic shielding materials. These materials play a crucial role in protecting devices from unwanted electromagnetic fields, ensuring reliable operation in a wide range of applications.

What is Electromagnetic Shielding?

Electromagnetic shielding refers to the process of reducing electromagnetic field strength by using materials that absorb, reflect, or conduct electromagnetic waves. This shielding can be achieved through various methods, utilizing different materials to block or attenuate electromagnetic radiation across a wide spectrum of frequencies. The effectiveness of shielding is typically quantified in terms of its shielding effectiveness (SE), measured in decibels (dB), which indicates how well a material can attenuate electromagnetic waves. The higher the dB value, the more effective the shielding.

Importance of EMI Shielding in Modern Applications

As technology advances, the prevalence of electronic devices continues to rise, leading to increased risks of EMI. This is particularly important in industries such as telecommunications, aerospace, medical technology, and consumer electronics. Effective EMI shielding is vital for:

- Protecting Sensitive Equipment: Medical devices, including MRI machines and pacemakers, require stringent EMI shielding to function without interference.

- Ensuring Communication Integrity: In telecommunications, effective shielding is essential for maintaining the quality of signals transmitted over distances.

- Preventing Data Loss: In IT and data centers, electromagnetic interference can lead to data corruption, making shielding crucial for operational reliability.

- Enhancing Safety: In industries such as aerospace and automotive, EMI can have dire consequences; effective shielding minimizes risks to both equipment and personnel.

Common Sources of Electromagnetic Interference

EMI can originate from various sources, both natural and man-made. Common sources include:

- Electrical Devices: Everyday appliances like microwaves and computers emit electromagnetic radiation.

- Radio Frequencies (RF): Mobile phones, Bluetooth devices, and Wi-Fi routers contribute to the RF spectrum pollution.

- Industrial Equipment: Equipment used in factories often creates electromagnetic fields due to large motors and transformers.

- Cosmic Sources: Solar flares and cosmic radiation can also introduce electromagnetic interference, particularly affecting high-altitude and space-borne systems.

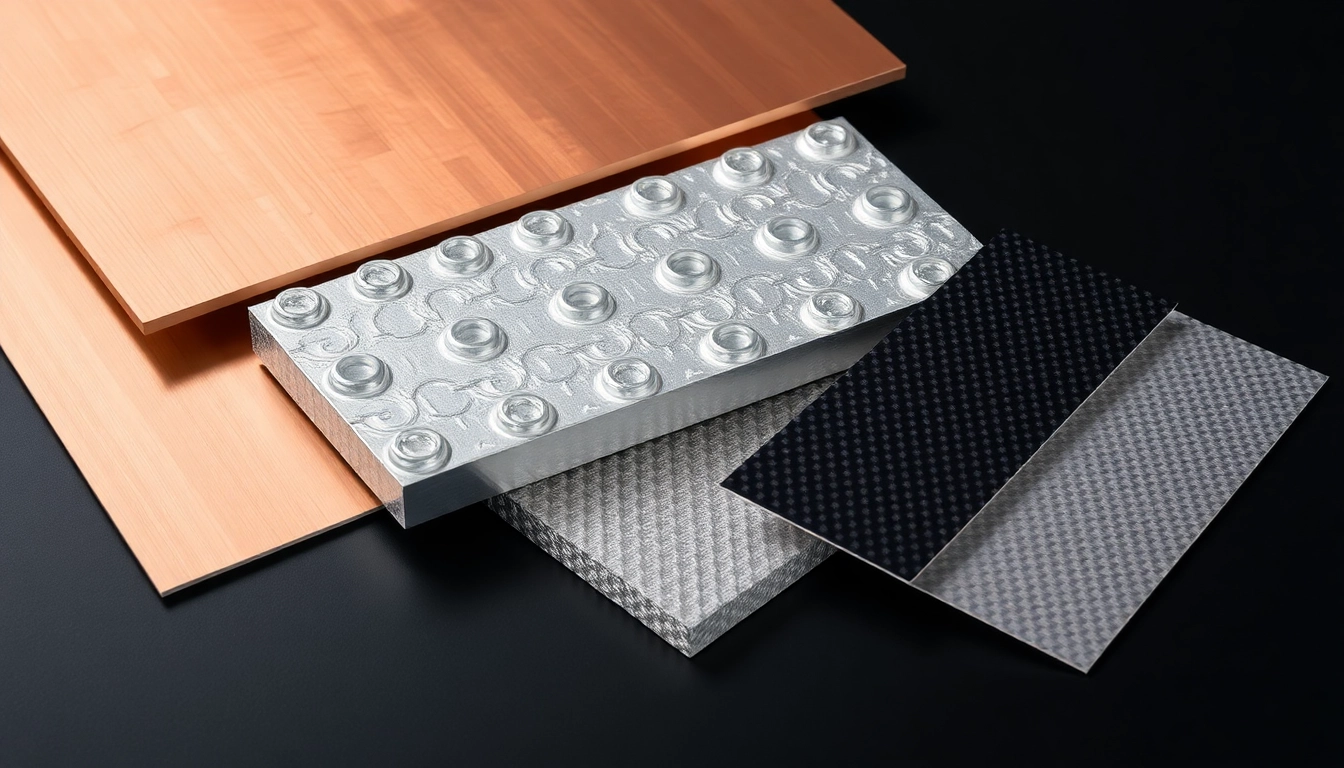

Types of Electromagnetic Shielding Materials

Metals: The Most Common Shielding Material

Metals are the most commonly used materials for EMI shielding due to their excellent conductive properties. They can effectively reflect and absorb electromagnetic waves, making them ideal for creating barriers against interference. Key metals used in shielding include:

- Copper: Highly conductive and effective in attenuating both electric and magnetic fields. Its low resistivity allows for efficient current conduction and heat dissipation, although it can be pricey.

- Aluminum: Lightweight and more cost-effective than copper, aluminum is widely used in various applications, including enclosures for electronic devices.

- Steel: Often used in industrial settings, steel provides substantial protective qualities due to its density and structural integrity.

- Nickel: Often employed in the plating of other metals, nickel improves corrosion resistance and maintains the efficacy of shielding.

- Brass: A copper-zinc alloy, brass is frequently used for connectors but can also serve as a base material for shielding due to its conductive properties.

Ceramics and Composites in Shielding

Ceramics and composites represent an alternative to metal for EMI shielding. These materials can be effective in specific applications, offering benefits such as lightweight composition and enhanced thermal stability. Common examples include:

- Conductive Ceramics: Materials like ferrites and perovskites can function as effective barriers against EMI, particularly at high frequencies.

- Composite Materials: The combination of metals with polymers or ceramics is emerging as a lightweight solution for EMI shielding, allowing designers to customize properties for specific applications.

- Graphene-Based Composites: Emerging materials that offer exceptional conductivity and shielding capabilities while being lightweight and flexible.

Conductive Polymers and Their Uses

Conductive polymers are increasingly being recognized for their potential in EMI shielding applications, especially in flexible and lightweight designs. These polymers can be infused with metals or conductive fillers, enhancing their properties. Examples include:

- Polyaniline: A conducting polymer that can be processed in various forms, including films, coatings, and composites, offering effective EMI shielding in lightweight applications.

- Conductive Epoxy: Often used in the assembly of electronic devices, these epoxies provide both bonding strength and EMI shielding.

- Carbon Nanotube Composites: By incorporating carbon nanotubes into polymer matrices, manufacturers create materials with improved conductivity and EMI shielding effectiveness.

Performance Characteristics of Shielding Materials

Electrical Conductivity and Magnetic Permeability

The performance of shielding materials hinges significantly on their electrical conductivity and magnetic permeability. Electrical conductivity allows materials to act as reflectors or absorbers of electromagnetic waves, whereas magnetic permeability determines how well a material can attenuate magnetic fields. Understanding these properties helps in selecting appropriate shielding materials for various applications.

Evaluating Shielding Effectiveness

Shielding effectiveness (SE) is typically tested under specific conditions and characterized by its ability to reduce electromagnetic waves over a defined frequency range. Measurements often utilize standardized testing methodologies, including:

- Insertion Loss: Represents the power loss when a signal passes through the shielding material.

- Reflection Loss: Measures how much of the incoming electromagnetic wave is reflected back due to the shielding material.

- Transmission Loss: Indicates the amount of electromagnetic energy that successfully transmits through the barrier.

These metrics are crucial for engineers in assessing the adequacy of shielding materials in their specific applications.

Durability and Environmental Resistance

For many applications, particularly in harsh environments, durability and resistance to environmental factors are paramount. Key considerations include:

- Corrosion Resistance: Metals exposed to moisture and other corrosive elements must resist degradation. Coatings and surface treatments can enhance longevity.

- Temperature Resistance: Materials should maintain their shielding effectiveness across temperature variations that might be experienced in their operational environments.

- Mechanical Strength: The material needs to withstand physical stress without losing performance, particularly in mobile or industrial applications.

Applications of Electromagnetic Shielding

Industrial and Consumer Electronics

In the realm of consumer electronics, electromagnetic shielding is critical for devices like smartphones, laptops, and wearables, where compactness and functionality intersect. Conversely, industrial applications often deal with larger equipment that requires robust shielding solutions to protect against strong EMI sources. Notable applications include:

- Mobile Devices: Electromagnetic shielding is employed to enhance signal quality and reduce interference in smartphones and tablets.

- Computers: EMI shielding is crucial in computers to prevent disruptions that could lead to malfunction or data loss.

- Home Appliances: Shielding in microwaves and other appliances helps minimize interference with other electronic devices.

Medical Equipment and EMI Protection

The medical field relies heavily on EMI shielding as devices such as MRI machines and ultrasound equipment operate in environments where precision is critical. EMI can severely affect their operational efficacy, necessitating stringent shielding measures. Examples include:

- Imaging Devices: MRI and CT machines require effective shielding to ensure clear images are produced without interference.

- Electrocardiograms (ECGs): Devices like ECGs need shielding to ensure accurate readings, free from external electromagnetic noise.

- Telehealth Equipment: As telehealth technologies become more prevalent, maintaining signal integrity through effective EMI shielding is essential.

Automotive and Aerospace Industries

The automotive and aerospace industries face unique challenges regarding EMI. As vehicles and aircraft become more reliant on electronic systems for navigation, communication, and safety systems, effective EMI shielding becomes paramount. Key areas of application include:

- Navigation Systems: Effective shielding ensures that guidance systems function without interference from other electronic systems within the vehicle or aircraft.

- Communication Systems: Shielding prevents interference in communication systems used for pilot and vehicular communication, ensuring safety and reliability.

- Sensor Technology: Sensors used in various systems must operate without interference to ensure accurate detections and measurements.

Choosing the Right Electromagnetic Shielding Material

Factors to Consider When Selecting Materials

The selection of an appropriate shielding material is critical and must consider several factors, including:

- Frequency Range: Shielding needs vary across different frequencies, so understanding specific application requirements is essential.

- Material Properties: Evaluate the specific properties of potential materials, including conductivity, weight, and flexibility.

- Cost vs. Performance: Weighing the cost against the performance benefits will help in making a balanced decision.

Common Mistakes in EMI Shielding Design

Despite its importance, EMI shielding design can be fraught with pitfalls. Common mistakes include:

- Inadequate Material Selection: Choosing materials that do not suit the frequency range or operational environment can lead to ineffective shielding.

- Neglecting Gaps: Gaps in the shielding structure can significantly reduce effectiveness, so attention to seals and closures is critical.

- Overcomplicating Design: Simplifying designs while ensuring adequate shielding can optimize performance and reduce costs.

Future Trends in Electromagnetic Shielding Technologies

As industries evolve, so do the demands placed on EMI shielding technologies. Future trends may include:

- Nanotechnology: Advances in nanotechnology may lead to the development of ultra-thin, highly effective shielding materials that maintain flexibility and lightweight properties.

- Smart Shielding: Incorporating sensors and smart materials that can adapt to varying electromagnetic environments could revolutionize shielding designs.

- Sustainability: Increasing focus on eco-friendly materials and processes is expected in the production of shielding materials, leading to a more sustainable approach to EMI protection.

Conclusion

The growing prevalence of electronic devices and systems in our everyday lives necessitates a keen understanding of electromagnetic shielding materials and their applications. As we move towards an increasingly digital future, the importance of effective EMI shielding cannot be overstated. From consumer electronics to critical medical applications, the right materials must be chosen to mitigate the risks of electromagnetic interference, ensuring safety, reliability, and performance in a world increasingly driven by technology.

Leave a Reply